Detail Engineering: from design to complete plant documentation

Detail engineering is a highly interdisciplinary process that is dedicated to fully detail and fix the planning packages of the disciplines involved. While (extended) basic engineering is mainly dedicated to construction, approval and plant planning that influence each other, the detail engineering implies the mutual dependencies and influences of plant engineering, electrical engineering and building services.

In many cases, it is advantageous to commission the executing company or companies with the detail engineering. To enable this, we are the right partner for the coordination and supervision of the individual trades in this phase.

Detail Engineering

- Detail engineering with CAD/ 3D visualization

- 3D piping and steel structure design

- Detail engineering of special solutions (Inventor)

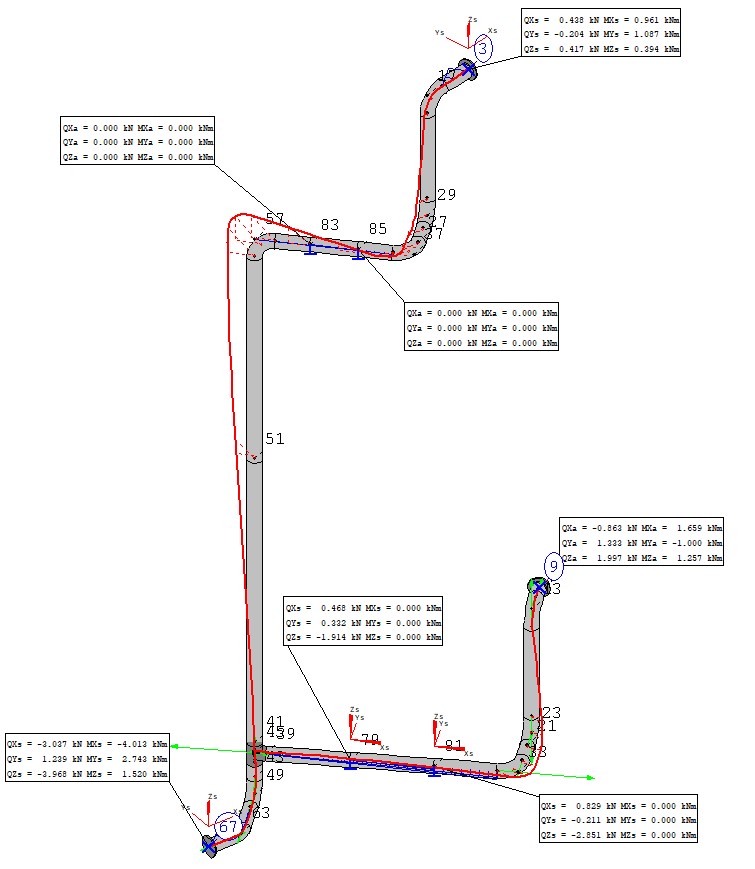

- Pipe statics (Pipe 2)

- Static and dynamic structural analysis of piping systems

- Static proofs steel construction

- Structural analysis of piping systems

- Stress calculations/ pressure surge calculations

- Design of equipment, pipe classes and components

- Specification of essential quality requirements of main components and fittings

- Preparation or detailing of tender documents

- Flange verification

- Production documents

- Operating manuals

Case Study – Detail Engineering

In addition to the planning of new production plants, the expansion of existing plants, such as the replacement of agitators or the connection of new raw materials, is also part of our services. Especially for reaction plants which have been in operation for many years and which have already been modified several times, a detailed planning of the planned changes is indispensable in order to avoid unnecessary downtimes.

For example, we were commissioned by a medium-sized customer to plan the expansion of an existing production facility to include an additional mixing vessel. Again, we started with a 3D scan of the existing situation in order to carry out a detailed 3D plant design. The derived isometrics and our created assembly concept were the essential part of the tender documents we prepared for this project. They were also the indispensable basis for obtaining comparable offers for the implementation of the project

During the implementation phase of a plant construction project, a close support of the executing companies is essential. In addition to the legal requirements (BImSchG, TA Lärm, TA Luft, AwSV, Machinery Directive, BetrSichVO, LBO, ...), it is also important to ensure the compliance with the company's internal specifications. If deviations are detected too late, they can often be associated with high costs. In order to avoid such deviations or at least to detect them at the earliest stage, as well as to reduce negative effects on schedule and budget, project management and construction supervision are essential parts of our service range.